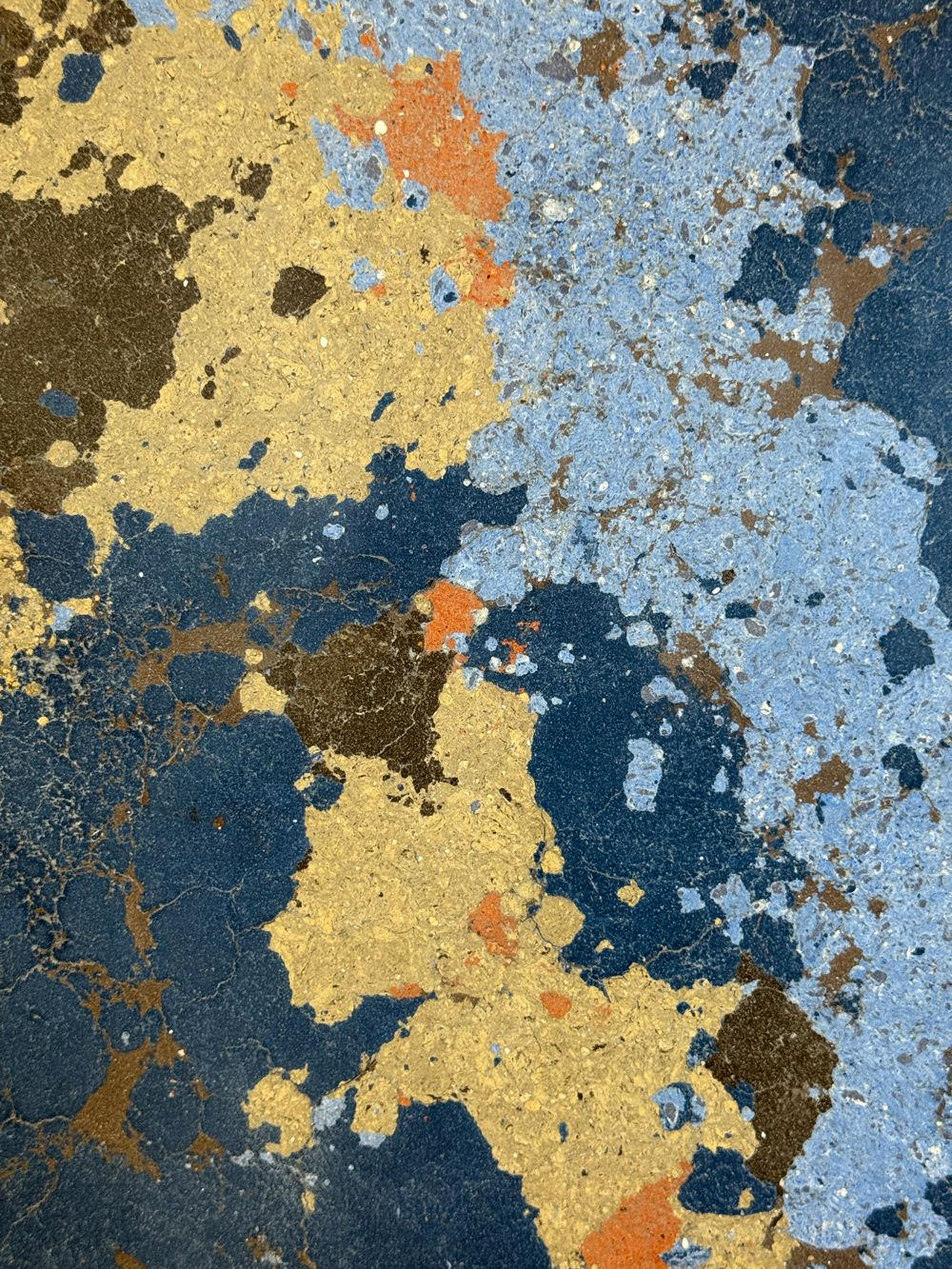

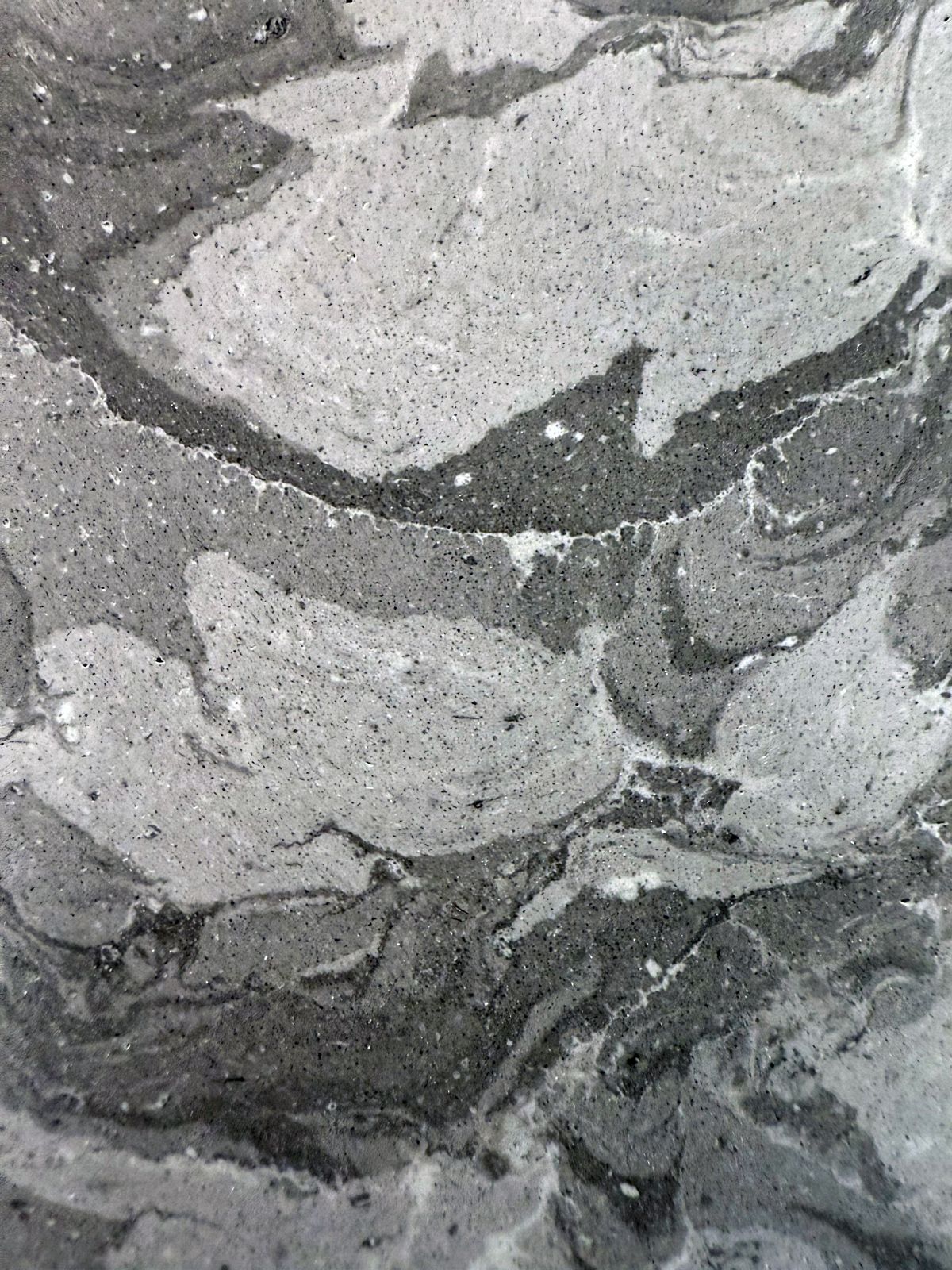

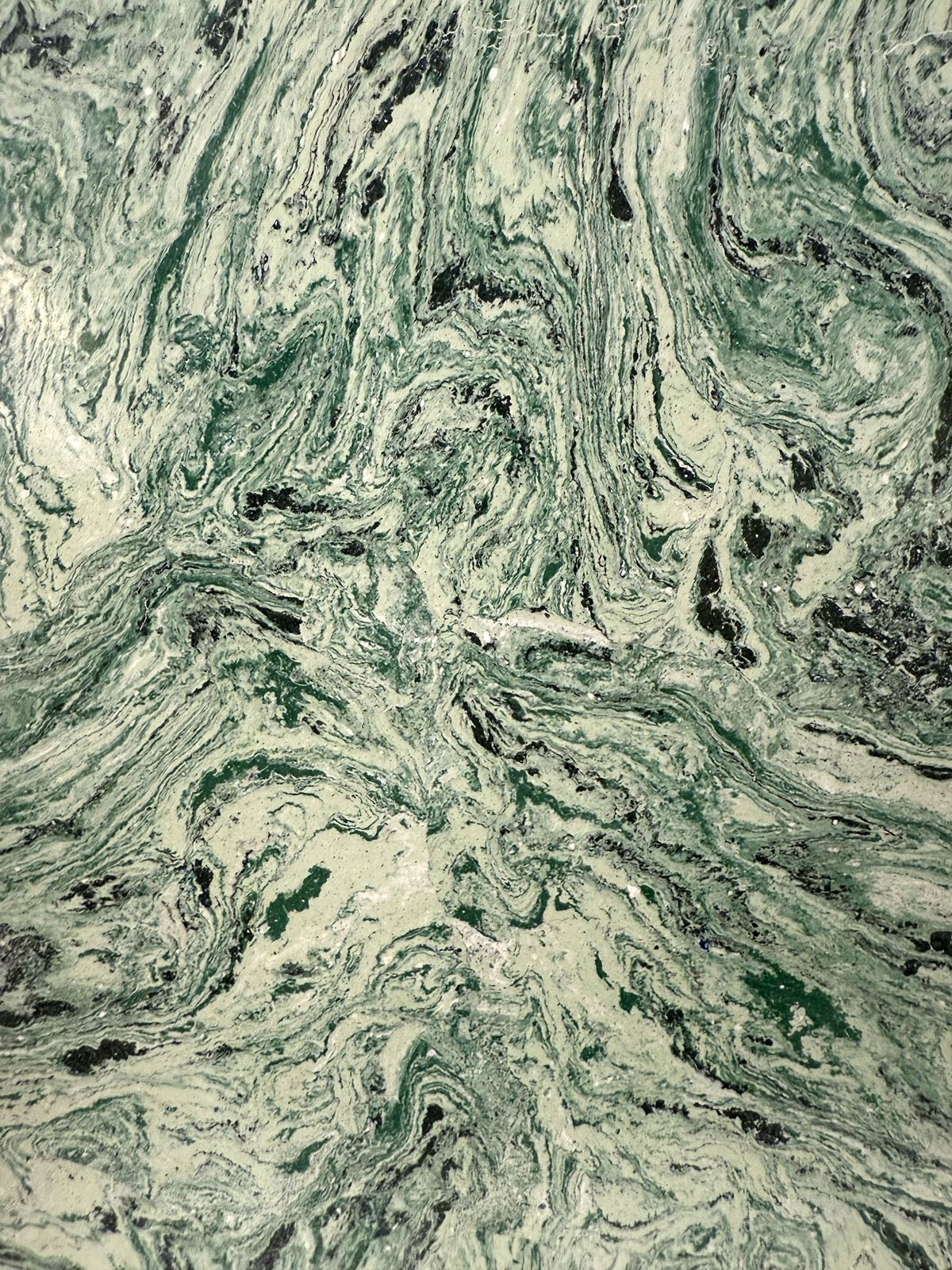

"Stucco Marmo" (also known as Scagliola) is one of the plaster finishing techniques developed in Europe, creating marble patterns by kneading gypsum and pigment. The finish surface is densely polished, having depth and gloss that can be mistaken for real marble, and is characterized by being finished expressively by handwork of craftsmen.

Actually, this technology is used in very special places in Japan as well. The entrance hall of "Hotel Kawakyu" in Shirahama, Wakayama Prefecture -- the 24 blue pillars supporting the gold leaf ceiling are all made of this Stucco Marmo. The pillars, which are cold and smooth to the touch, are not marble, but "kneaded stone" created by being kneaded, applied, and polished by craftsmen's hands.

This time, I had the opportunity to learn such traditional yet modern plastering technology at "Stucco Italiano" in Vicenza, Italy.

"Stucco Marmo" is also known by the alias "Scagliola" depending on the region and era. Especially in 18th century Europe, it was called by this name and developed as advanced decorative technology coloring the interiors of palaces and theaters at that time. In English-speaking countries, the name "Scagliola" is common, and searches with this word are increasing in recent years.

In Italian, "Scagliola" comes from "stone chips = scaglie", simply expressing its character as stucco decoration imitating marble. Stucco Marmo and Scagliola refer to essentially the same technology, with only differences in usage and name.

Texture not obtainable with industrial products

It has a composition adapted to the modern building material environment, not gypsum and glue like in the old days, and stable workability and beautiful finish can be obtained. Still, the expression of the finish depends on the movement of the "hand". The marble pattern and gloss appearing on the surface change greatly with slight changes in pressure and angle -- it is a finish where craftsmanship truly lives.

Learning senses, not just techniques

Mr. Zeljko, who instructed the training, is a well-known craftsman locally, and his teachings were always practical and logical, which was very valuable for deepening our understanding.

What was particularly impressive was the trowel used to finish the clay-like material smoothly. Mr. Zeljko said he had this trowel custom-made by a blacksmith, a very heavy one, structured to transmit force firmly without losing to the material. Its high finishing precision was exactly proof that tools and technology became one.

After returning to Japan, when we were looking for a similar trowel, we were able to receive a special trowel from "Kajiwara Trowel Manufacturing" by chance. Japanese craftsmanship, which has a long history in iron processing, resonates with Italian plastering culture in this way, giving new possibilities to our construction.

Richness brought by "Not being uniform"

In this finish, "perfect uniformity" is not necessarily beautiful. Faint unevenness and difference in color shading rather create depth and taste. This expressiveness that seems to give "breath" to space is a charm not found in mass-produced building materials.

Versatility usable for curves, floors, and furniture

The Stucco Marmo used this time has evolved as follows compared to traditional materials.

- Thin coating high-speed construction: Fits fast drying, can significantly shorten work time.

- Improved water resistance and durability: Less swelling and deterioration even in humid environments, compatible with water areas.

- Ultra-low VOC: 1/200 or less of EU standards, significantly reducing environmental load on indoor space.

- Physical strength (6H hardness): With a densely polished finish, it is applicable to floors, tabletops, furniture, etc.

- Design freedom: Various expressions such as marble style, limestone style, alabaster style etc. are possible depending on how layers are stacked and color combinations.

"Culture of Texture" understood only by experiencing

This finish has a charm that cannot be fully conveyed by photos or samples. By actually constructing, polishing, and seeing its expression in the light -- by touching that process, you can experience the magnitude of the impact the material gives to the space.

1,000 Euros per square meter in Italy

At Stucco Plus, we bring back this technology and refine it further while reviewing workability and cost aspects in a form suitable for the Japanese architectural environment. While keeping the charm of the material, we are pursuing more efficient and flexible construction methods.

Plastering giving "Air" to the finish

It is the power of this technique that influences not only the beauty of appearance but also the sense of temperature and comfort of the space. Through "applying", adding new texture and flow of time to the space -- we would like to cherish such a way of plastering in the future.

We look forward to your consultation

If you are interested in Stucco Marmo (Scagliola) or considering construction, please feel free to consult us first. Stucco Plus will propose with materials, technology, and thoughts for space.

Finally, I would like to express my sincere gratitude to Mr. Zeljko who gave me this valuable learning opportunity, and Ms. Chiara who supported me devotedly every day.